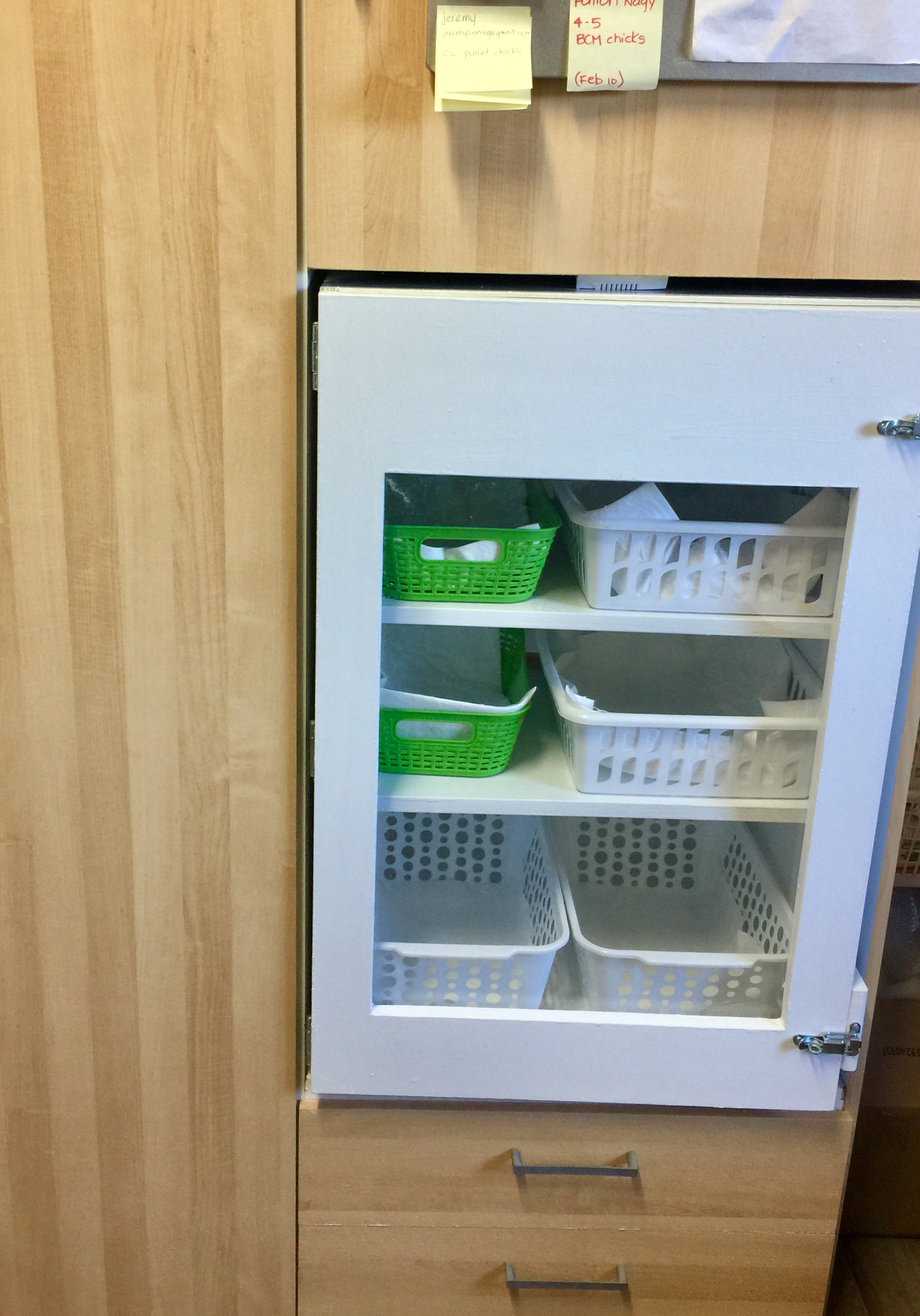

Homemade hatcher disaster! Please help troubleshoot.

Home made cabinet with airholes & IncuKit XL

Temp and humidity were perfect. 99.5/65-70%

66 eggs went in lockdown yesterday (alive & well)

Today- day 20: 3 pips this morning. Came home to find them dead after pipping. No further sounds or activity coming from the rest of the eggs. Normally they'd be well into hatching, with lots of pips.

My suspicion is that since the hatcher was recessed into a cabinet, there was inadequate ventilation....? Another clue things were amiss was water was dripping down the door.

Shelves are solid but do have gaps front and back for air to move through. Painted with latex paint.

I've since pulled it forward out of the cabinet so the vent holes are exposed to room air. I think it's too late and they're all dead though.

Ugh.... why did we mess with a perfect system? They were hatching great in the sportsman

Any thoughts appreciated.

Home made cabinet with airholes & IncuKit XL

Temp and humidity were perfect. 99.5/65-70%

66 eggs went in lockdown yesterday (alive & well)

Today- day 20: 3 pips this morning. Came home to find them dead after pipping. No further sounds or activity coming from the rest of the eggs. Normally they'd be well into hatching, with lots of pips.

My suspicion is that since the hatcher was recessed into a cabinet, there was inadequate ventilation....? Another clue things were amiss was water was dripping down the door.

Shelves are solid but do have gaps front and back for air to move through. Painted with latex paint.

I've since pulled it forward out of the cabinet so the vent holes are exposed to room air. I think it's too late and they're all dead though.

Ugh.... why did we mess with a perfect system? They were hatching great in the sportsman

Any thoughts appreciated.